STEIN MAGIC SAND FOR ROAD CONSTRUCTION.

Stein magic sand is an additive used to increase the strength and hardening properties of soil.

It achieves outstanding performance and is highly praised at many sites for its shortening of the construction period,

reduction of the construction cost, and durability after construction.

Why choose STEIN- MAGIC SAND to construct roads?

1. Easy and quick

2. Low cost

3. Results and reliability

- The characteristics of soil hardening agent “ STEINE ”

- The standard “ STEIN ” blending ratio

- Necessary considerations to effectively use “ STEIN ”

- In the Construction works

- The various construction examples “ STEIN ” is available

- The types of “ STEIN ” product, their usages and specification

- The “ STEIN ” construction system

- At the mixing in-place soil Method (work flam)

- The workflow of the mixing in-place soil method

- The morter system of “ STEIN ”

- The construction examples with which “ STEIN ” is employed

- The chemical ingredient of the “STEIN” product

- The test data on the harmlessness of the “ STEIN “ Products

- The physical and dynamic property of “STEIN”

The characteristics of the soil hardening agent “ STEIN “

| Why choose STEIN- MAGIC SAND to construct roads? 1. Easy and quick 2. Low cost 3. Results and reliability Stein magic sand is an additive used to increase the strength and hardening properties of soil. It achieves outstanding performance and is highly praised at many sites for its shortening of the construction period, reduction of the construction cost, and durability after construction. The Stein magic sand ingredients can stand the test of time as that of a concrete. |

The effective reuse of site soil ↓ Unnecessary replacement of marketable aggregate In-place applicability and economical construction cost. |

| 2. Reduced construction thickness with high load dispersion effects by STEIN The official test result indicates that hardened base courses by STEIN have high numerical values not only at the uniaxial compressive strength but at the bending strength and the shear modulus, thus demonstrating high load dispersion effects. Therefore, the construction thickness of road substructures can be reduced to be a certain extent. In the case of the road on which the supporting capability of subgrades had been enhanced by long term traffics, additional 20cm base course construction on the subgrades could sustain high load heavy traffics. |

Simplification of the construction process ↓ Shortening of the construction period |

| 3. Low crack growth rate with low contraction and expansion nature. As the hardened soil by STEIN can be hardly affected by air and earth temperature, the crack development on construed objects is extremely low. |

Frost heave damage prevention effect ↓ Unnecessary repair of the structure |

| 4. Extremely low permeability and heat conductivity. As STEIN hardens on-the site soil and uses no carried-in aggregate materials such as gravels and sand, the STEIN construction keeps extremely low permeability and heat conductivity, thus STEIN construction cut off heal transfer and water lows generated between the above and the under constructions. |

Construction and expansion is small ↓ Unnecessary repair of the structure |

| 5. Excellent acid resistance. The hardened soil by STEIN has higher acid resistance nature as compared with products made by using ordinary Portland cement. Therefore, STEIN is ideal for construing base floors of live sock hutches, paddocks, Barnyard manure reservoirs, which are susceptible to acid discharged by livestock excreta. |

Excellent acid resistance ↓ Unnecessary repair of the structure |

| 6. High evaluation in the point of environmental protection. The projects using STEIN are natural in color and soft in feeling as the are made up of soils in place adapt themselves easily to the neighboring circumstance. In such environmental protection areas as the public parks and templ-shrine areas. STEIN is ntilized widely in the construction works of promenades, squares, cycling roads, and jogging courses. |

The effective reuse of site soil ↓ Landscape protection |

The standard STEIN Blending ratio (Standard SBR)

- STEIN-R … in the case of building subgrades, 8 to 12% to the maximum dry density weight of the soil STEIN is blended with.

In the case of building based courses, 4to10% to the maximum dry density weight of the soil STEIN is blended with.

One experimental case performed by blending

STEIN-R with 1.895Kg maximum dry density weight decomposed granite soil shows the diversity of the CBR rating depending on the SBR.

The SBR rating of that decomposed granite soils is 0.4% without STEIN . 7.6% with 5%SBR, 12.0%with 7.0%SBR, 25.1%with10.0%SBRand 39.0%with 14.0%SBR. - STIN-N … The SBR 8.0 to 30.0%in the same construction cases as STEIN-R

- STEIN-MH… The SBR 4.0 to 8.0% to the moist density weight of the natural water content soil.

The proses in determining the SBR

The determination of the SBR is the most important matter to be considered prior to the actual construction. And it’s process is as follows.

At first. The objective construction strength must be established. Considering various construction site condition such as temperature, earth nature , water level , soil nature and so on.

Secondly, conduct the room experimentation in order to figure out and determine the standard SBR using a soil samples extracted from the planned construction site.

Finaly, determine the SBR applying the in-place modification index calculated taking the anticipated change index caused by the actual construction works, strength reduction caused by the difficulty of the water content management and different ways of blending methods into consideration.

Necessary considerations to effectively use STEIN in the construction works.

- When the rainfall is expected during the construction Period, cover the construction spot with waterproof sheets to prevent water content of the soil from getting excess content.

- When the water content of the soil is not suitable to mix with STEIN, spray water to the soil prior to or after mixing STEIN and well mix the soil with water to attain the optimum water content of the soil.

- pay attention to maintain the appropriate water content throughout the construction work.

Excess water content causes rubber tired rollers and other construction machines unable to do effectively operate to Get necessary rolling compaction.

Even if rolling compaction level is achieved, the surface of the construction might not be smooth enough because of adhering and sticking soil to the machines. - During the winter period or cold districts in which the minimum temperature of the day is under 5 degree Celsius, hardening effects of STEIN is not expected. Therefore, avoid construction works with STEIN.

- Even in the construction of public park promenades and stabilization works of athletic fields which soft and natural soil color feelings are more important than high construction strength and abrasion resistance property are, and in the construction of temporary roads for another main construction projects and temporary parking lots which base courses are not paved and exposed, determination of the SBR is the most important matter because depending on the soil nature, growth of surface wears and cracks are apt to happen during their use.

The various construction examples STEIN is available.

- The construction of upper and lower layers of the general roads which are traditionally constructed by asphalt concrete or cement concrete.

- The contraction of base causes of roads or trails such as agricultural. Forestry and temporary construction roads. The surface asphalt concrete layers are necessary to be placed when certain level of abrasion resistance property is required.

- The light pavement constructions such as public parks, Promenade roads in parks, public playgrounds, jogging courses, cycling roads and walking passes or parking lots of the shrine-temple areas with which high construction strength and abrasion resistance property, usually required in general roads, are not necessary.

- The construction of the underbase of tennis courts and volleyball courts. Also the construction of gate-ball fields and athletic courses.

- The construction of walking paths on the school campus. The prevention works of dust clouds and muddiness in public playgrounds.

- The construction of live stock hutch floors. Paddocks, barn manure reservoirs, store house floors. Agricultural workshops, and so on.

- The construction of fish breeding ponds, water reservoirs, drainage diches, and the solidification works of water ditch bases.

- The solidification treatment of muddy sewage dredged up from rivers and oceans.

- The stabilization treatment of soft ground and subgrades.

The types of STEIN products, their usages, and specifications.

- STEIN-R

STEIN-R is standerd type of STEIN products and mainly used for the construction works of base courses and subgrades of roads in “ the mixing in-place soil method” or the mixing carried-in soil method.

In the mixing in-place soil method, STEIN-R is placed and spread equally on the designed road surfaces and blended with soils in there by construction machines such as stabilizers.

In the mixing carried-in soil method. Soil is carried in massively from remote areas to the nearby workshops from roads and blended with STEIN-R.

Then those mixed soils are carried again and laid on the roads surfaces. The former method is suitable in such conditions which soils existing on the planned roads are suitable for blending with STEIN.

Is soils on the roads lines are not good in quality to blend with STEIN, the latter method is adapted.

Selection of the method should be done taking other various factors on the construction sites into considerations.

In either method, soils must be compacted firmly at the optimum water content state and completed with the final watering works. - STEIN-M

STEIN-M is employed as the mortar system in such areas as the construction sites are on a steep slope or a muddy soft ground and rolling compaction is not available, or the obstacles hinder

The construction machines to advance to the site, STEIN-M is blended with soils and used as a workable paste.

This is also utilized to solidify burned refusal ashes And industrial waste material. - STEIN-MH

STEIN-MH is used to solidify dredged muddy sewage and organic soft soils.

STEIN-MH is able to gel high water content sewage materials and organic soft soils in relatively - EC-type

STEIN-EC is produced by utilizing burned refusal ashes and used for the soil improvement agent.

| Standard specification | |

| Standard specification | Heavy metals insoluble chemicals |

| R | M | MH |

| Road mixing | Mortar | Sludge treatment |

| R+α(chemicals ) |

M+α (chemicals) | MH+α(chemicals) |

| Road mixing | Mortar | Sludge treatment |

| Standard specification | |

| Standard specification | Heavy metals insoluble chemicals |

| EC-5 | EC-3 |

| Road mixing | Sludge treatment |

| EC-5+α(chemicals) |

EC-3+α(chemicals) |

| Road mixing | Sludge treatment |

The STEIN construction system at the mixing In-place soil method (work flow )

| Work contents | Employing construction machines | Tests and checks | Precaution | |

|---|---|---|---|---|

| Step 1 The in-place soil investigative tests |

Determine the designed road strength at the Uniaxial compressive strength and the road thickness. | The test to figure out the optimum compassion water content of the soil, the test on the particle size distribution of the soil, the certification of the designed road strength value at the uniaxial compressive strength. | ||

| Step 2 preparation works |

a) Rake out subgrades and base courses and level off those surfaces to the designed height. b) Pick up and remove completely stones, debris, and organic matters such as tree toots which are likely to hinder soils from mixing up to the construction thickness. c) Compact soils averagely to the extent that every portion of the road can hold the same compaction strength. d)Set up adhoc wooden measuring scales at every 15meter distance to check the designed height and thickness of the road against the ongoing features. |

Bulldozers. Motor graders, Macadam loader, Rubber tired rollers. |

Measure the in-place soils water content, the compaction density, and the bearing capacity. | a)The bearing capacity of subgrades and basecourses must be the same at every portion. b)When the compaction density is 75% (bearing capacity K30 is under 6.35) the different construction method might be taken into considerations. c)The double layers construction technique should be adopted if the part of the road appeared to be too weak in strength. |

| Step 3 Raking and leveling works |

a) Rake out fully to the bottom of designed depth of the road. b) Crash soil particle into as small bit as possible. c) level off the surfaces of crushed soil . d) Dry and adjust the water content of soil if necessary. By raking soil upside down. e) When other aggregate materials are needed to be mingled. Spread out them on the surface evenly before missing them up and then mix them thoroughly. |

Bulldozers, Motor grader Stabilizers, rotor |

Measure the water content. Check the particle Size of crushed soils to make it sure it is suitable level. |

After crushing soil. Execute the adjustment of the Optimum water content of soil to rolling compaction and then mix them up completely. |

| Step 4 Spreading STEIN and mixing up with soil |

a)Place designed amounts of STEIN per square meters over the construction site and spread it evenly. For instance, using wooden rakers. b) Mix up STEIN with soil so that STEIN can be thoroughly and equally mingle among soil. c) Level off the soil surfaces mixed up with STEIN. |

Bulldozers (rotor), Stabilizers, M263 (soil load mixers ) |

a) Taking advantage of formally put up ad-hoc scales, check and make it sure, that STEIN is mixed enough to the extent of designed construction depth. b) Make test pieces for the compressive strength test |

Mixing until so that the soil and STEIN have uniform color throughout. |

| Step 5 Rolling compaction |

a) Execute the rolling compaction coverage averagely at 16 items or more. While pushing down stones which may appear out onto surfaces during the work. b) Shape road surfaces along the longitudinal direction and the transverse direction to adjust the road figures to the designed dimension, taking advantages of formerly put up ad-hoc measuring wooden scales. c)Correct ruggedness employing hand rakes. d)Employ rollers 3to4 times as the finish-up rolling compactions. |

Macadam loaders, rubber tired rollers, bulldozers, Motor graders. |

a) Taking advantages of ad-hoc scales set up formerly measure the road figures and check them if shaping works could be done properly. b) Measure Density solid-tightening. |

a) Depending on subgrades states, choose the ways of rolling compaction with increased gradually b)the rolling compaction should be completed within 4 hours after the STEIN is spread and mixed up c)Avoid abrupt and sudden changes of directions in roller operation. |

| Step 6 Curing |

a) Water the constructed roads at the ratio of 0.3 litters of water to 1Kg of STEIN. B) Cover the roads by sheeting materials to prevent from freezing when the temperature goes down under 5 degree Celsius. |

a) Check the construction thickness and the uniaxial compressive strength by taking up core samples of the constructed roads. b)K30 Measure the bearing capacity. |

The workflow of the mixing in-place soil method

Ranking-out of soil and leveling-off.

(bulldozer, rake dozers)

Equal placement of the STEIN-R on the leveled soils.

Spreading-out of the STEIN-R equally on the sites out of packages.

Mixing up of the STEIN-R with the in-place soil to the bottom of the designed construction thickness.

Leveling-off of the road surfaces.

Rolling compaction.

Rolling should be executed as soon as the leveling-off work is finished.

Leveling-off

after rolling compaction.

Watering.

Water the road to be extent that water goes down to the bottom of the designed road thickness.

Completion.

The mortar system of STEIN

1,shaping-up

The construction base.

Human power

Bulldozers,

Rubber tired rollers.

- level-off and shape-up the designed construction base bay bulldozers and human workers.

- Execute the rolling compression by rubber tired roller impact rollers or handy wood embankment slope compacters as required.

2, Mixing-up

STEIN with soil to make the STEIN mortar

Mortar mixer

- On the basis of the strength test by field soil, to determine the combination of soil and STEIN.

To make each of the catch basins to be weighed each material comes out. - And mixed in a mixer various materials were weighed in catch basins.

(Slump around 15cm)

3, Placing the STEIN Mortar onto

The construction base

Unicycle. Other

- It is important to note design thickness, width, and length, etc..

Hitting set on top of the soil, moisture must be adjusted surface finish is required curing and watering

4, Finishing

Trowel

- Finishing touches on the surfaces of the construction by using wooden trowels and metal trowels.

5, Curing

Straw mat, Other

- Curing by the air curing is a general rule. But when the road is put under the direct sunlight, cover it with sheets to shut the sunbeam.

Water over the road as necessary.

The construction examples with which STIEN is employed

Constructions of basecourses and sub basecourses of roads.

Constructions of forestry roads.

Constructions of promenade roads.

Constructions of barnyard manure reservoirs.

Backfilling of plumbing works.

Electric prop areal root hardening constructions.

River bottom repair constructions

Soft ground improvement construction.

Sludge treatments.

Hardening of cover soils and embankments

Solidification of incinerated ashes and burned ashes.

Safety disposal of heavy metals.

The chemical ingredient of the STEIN products

An outward appearance of the STIN products is quite similar to that of Portland cements. However, the STEIN products are the inorganic chemical medicament manufactured in special technologies and byways of production.

The STEIN differ in grade among products Depending on the manufacturing processes and are entirely free from toxic substances.

| SiO2 | CaO | AI2O3 | Fe2O3 | SO3 | MGO | 不溶残物 | その他残り | 強熱残量 |

|---|---|---|---|---|---|---|---|---|

| 23.0% | 60.0% | 5.0% | 2.0% | 2.2% | 2.0% | 0.3% | 4.5% | 1.0% |

SIO2 rate: 23⁄5+2.0 = 3.3

Alumina iron rate: 5⁄2.0 = 2.5

Hydraulic rate: 60⁄23+5+2.0 = 2.0

The test data on the harmlessness of the STEIN products

(Solubility test conducted by the Hokkaido environmental science technology center in September 2004 )

The test was conducted by producing hardened samples of 1Kg STEIN-M mixed with 300cc demineralized water and by the way of solution directed by the environmental agency notice No. 46.

| Name of harmful substance | weight of harmful substance (mg) com out to 1 litter of water. | Critertion set by the Environmental agency |

|---|---|---|

| Cadmium | 00.001 > | 0.01 ≥ |

| Total cyanogens | ND (0.1 > ) | ND |

| Inorganic phosphorus | ND (0.1 > ) | ND |

| Lead | 0.009 | 0.01≥ |

| Hexavarent choromium | 0.04 > | 0.05 ≥ |

| Arsenic | 0.005 > | 0.01 ≥ |

| Total mercury | 0.0005 > | 0.0005 ≥ |

| Alkylaiting mercury | ND (0.0005 > ) | ND |

| PCB | ND (0.0005 >) | ND |

| Selenium | 0.002 > | 0.8 ≥ |

| Fluorine | 0.4 | 0.8 ≥ |

| Boron | 0.02 > | 1 ≥ |

- The environmental agency notice No. 46

The physical and dynamic property of STEIN

A. The physical property test ( JIS R 5200 ) Nippon University manufacturing technology department

| Type of cement | Grade | Specific Gravity | Fineness | Setting | ||

|---|---|---|---|---|---|---|

| Specific Area (cm2/g) | Water Ratio (%) | Starting Time (H-M) | Finishing Time (H-M) | |||

| STEIN | R M |

3.08 3.08 |

5293 5253 |

33.0 33.0 |

0-16 0 -15 |

2-20 2-10 |

| Porland Cement | 普 通 ➀ 早 強 ➁ 超 早 強 ➂ |

3.17 3.13 3.11 |

3260 4450 6050 |

27.5 29.2 33.8 |

2-31 2-25 1-46 |

3-45 3-44 3-10 |

- Data of Portland Cement 1~3 Cement association of Japan

- Normal

- High early strength Portland cement

- Sper high carlystrength Portland Cement

The particle size of STEIN is much smaller and the specific surface area is larger as compared with those of Portland cement

Because of the special treatment given during the manufacturing processes.

Therefore, STEIN can contain smaller particle of soil than Portland cement can.

STEIN begins to coagulate soon and end coagulation in much shorter period of time attaining necessary strength than Portland cement does.

All these mean the period of curing can be greatly shorten by the employment of STEIN.

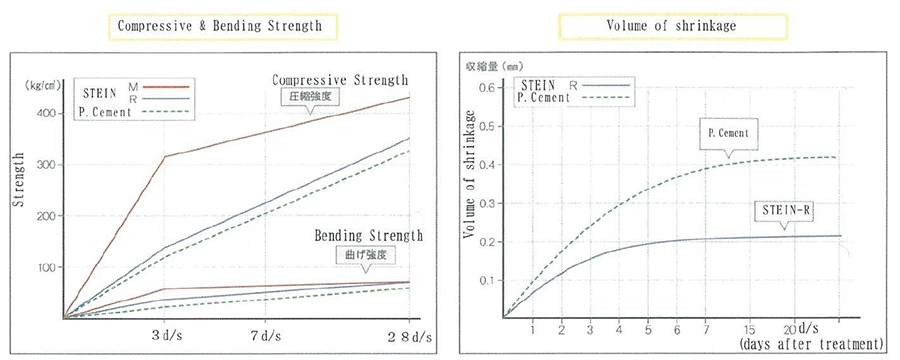

B. The dynamic properties test (JIS R 5201) Nippon university manufacturing technology department

| Type of cement | Grade | FLOW (mm) | Strength | |||||

|---|---|---|---|---|---|---|---|---|

| Bending (Kg/cm2) | Compressive (Kg/cm2) | |||||||

| 3d/s | 7d/s | 28d/s | 3d/s | 7d/s | 28d/s | |||

| シュタイン | R M |

209.5 210.5 |

34.3 58.2 |

49.3 63.5 |

62.5 73.8 |

123.7 315.0 |

211.6 348.2 |

331.0 431.6 |

| ボルトランドセメント | 普 通 | 206.0 | 35.7 | 52.0 | 72.7 | 147.0 | 219.0 | 358.5 |

Originally the test for STEIN-R should have been conducted under JIS-S1210, where the test pieces are required to be prepared by the compaction method. In this particular test, however, the test pieces of STEIN-R were prepared by the usual mortar method similar to be the others, in consequence of which the true value of STEIN-R could not be exhibited to its full potential.

The graph in the figure above, which means that it is a special production (the specific surface area is larger ) so that fine particles

STEIN compared to Portland cement.

This special production. Is STEIN it is possible to wrap up the tine soil particles beginning and the end of the condensation is very fast after setting. Compressive strength and bending are extremely high, mechanical properties and physical is excellent.

In addition, STEIN R. for contraction is smaller than that of the Portland cement mortar, cracking after drying is also reduced.

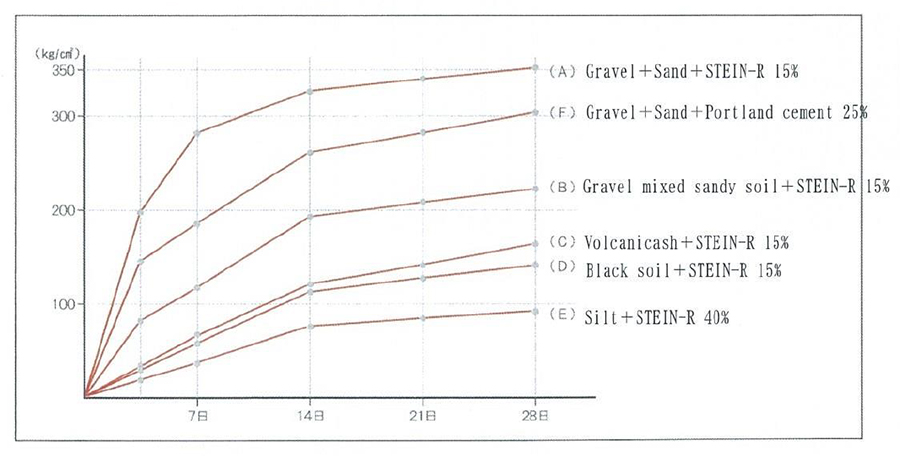

The compression test with various mixing soil specimens Stein R

The test pieces were prepared at the respective mixing ratio, as given below, to attain their 7 days strength at 30Kg/cm and up it was a test at a high blending 30-40% from the practical point of view

The specimens were made by Stein R. with the exception of (E ). By tamping method. Portland cement, ( E ) ( sludge ) was made by the mortar system.

Test piece :

- Gravel + Sand + STEIN-R 15%

- Gravel mixed sandy soil + STEIN -R 15%

- Volcanic ash + STEIN-R 15%

- Black soil + STEIN-R 15%

- Silt + STEIN-R 40%

- Grave + Sand + Portland cement 25%

( A ) ( Gravel ) + Sand + STEIN-R 15% ) showed higher compressive strength than that of ( F) ( Grave l + Sand + P Cement 25 %)

Especially in the early date strength, ( A ) is superior to (F) .

Even (E) ( Silt + STEIN-R 40% ) achieved more than 100Kg/cm in 28 days strength .

From which it is clear that STEIN can solidify any aggregate composition to an appreciable extent in strength.

Also STEIN can attain the aimed strength in the early stage of coagulation.

For these reasons, Stein found that choosing the aggregate depending on the formulation, to give considerable strength.

In fact, would not is possible for high such formulations using black soil and mud to be required to make as strong as this.